Magnesium ingot production

Introduction

Today, there is a global consideration to Magnesium as a light metal which has favorable mechanical and physical characteristics. Automotive and aluminum alloy industries are the main consumers of magnesium. There is a growing trend for replacing steel and aluminum parts of automobiles with magnesium alloys to decrease fuel consumption and CO2 emissions. Defense and aerospace industries are the other main consumers of magnesium and its alloys. Magnesium is one of the metals that is in the EU’s list of raw materials and strategic metals.

Two methods are used for magnesium production as a light metal of future: Electrolytic method and thermal method. The electrolytic process refers to the production process by using magnesite, carnallite and brine/seawater as raw materials, to produce anhydrous magnesium chloride or anhydrous carnallite through chlorination or dehydration, and then obtain magnesium metal by electrolysis. The electrolytic process requires large amount of power consumption (power consumption of 14500 kWh ~ 18000 kWh per ton of magnesium produced), and relatively larger investment, long construction period, and the environmental pollution problem incurred is difficult to be resolved.

Dolomite is one of the main raw materials for magnesium production by thermal reduction method and is considered economically. Magnesium thermal reduction is the method that uses natural gas as the process main fuel and nowadays china is the main producer of magnesium and its alloys in the world which produces more than 85% of world magnesium.

In 2011, Aramico as a knowledge based company started to build up a magnesium production plant in Iran using Pidgeon process. This plant was finished in 2013 and produces 6,000 tons per year magnesium ingot.

Application

Magnesium as a light metal is attractive for automotive industry and nowadays steel and aluminum parts of automotive are replaced with magnesium die cast parts. Aluminum industry is the second large consumers of magnesium in the world and approximately 30% of produced magnesium is used in aluminum alloy production industry. Other applications of magnesium is steel desulfurization, cast iron production, rocket fuel, military equipment, Cathodic protection sacrificial anodes, Ti reduction, Uranium purification process and etc.

Process

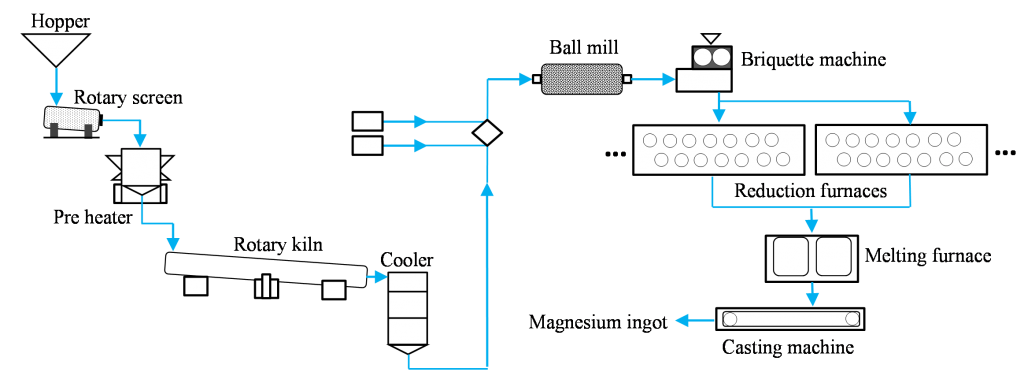

For the silicothermic reduction process, the dolomite is used as raw material, ferrosilicon as reducing agent and fluorite as catalyst. Under vacuum conditions, magnesium metal is produced by thermal reduction in the external heating reduction retorts (1200 – 1300 ). The silicothermic process is relatively simpler, with less investment, short construction period and less wastes handling input.

Electrolytic production of magnesium is another method that uses brines and seawater as the main raw material for magnesium production process. Today limited number of countries like USA, Israel and etc. use this method for magnesium production. Electricity consumption of this method is much more than thermal reduction of magnesium. Magnesium which is produced by molten salt electrolysis process is mainly used in defense and military industries.

According to Iran’s energy resources (natural gas), rich mineral reserves, access to target markets, rail and marine transportation infrastructures and skilled labor, this country is one of the attractive locations for magnesium thermal production industry. Using natural gas instead of coal as the Pidgeon process main fuel has many environmentally advantages could make this country one of the magnesium metal production centers in the world.

Calcination kiln, ball mill, briquetting machines, reduction furnaces, smelting and refining furnace, casting machine and material handling and storage equipment are the main machinery of magnesium thermal reduction plant. Aramico is capable of engineering design, construction and operation of magnesium ingot production unit by thermal silicothermic reduction method.

By identifying opportunities, conducting thorough research and performing tests at different levels we are developing technical knowledge for many industrial processes in the field of metallurgy, mining and renewable energy.

ARAMICO