Magnesium Ingot Production

Magnesium market

Magnesium and its alloys due to their low density, higher weight to strength ratio, chemical reactivity, mechanical properties and etc. are suitable materials for automotive and aluminum alloying industries. Replacing steel and aluminum parts of automotives by magnesium and its alloys, results in lighter cars, lower fuel consumption and environmental pollution.

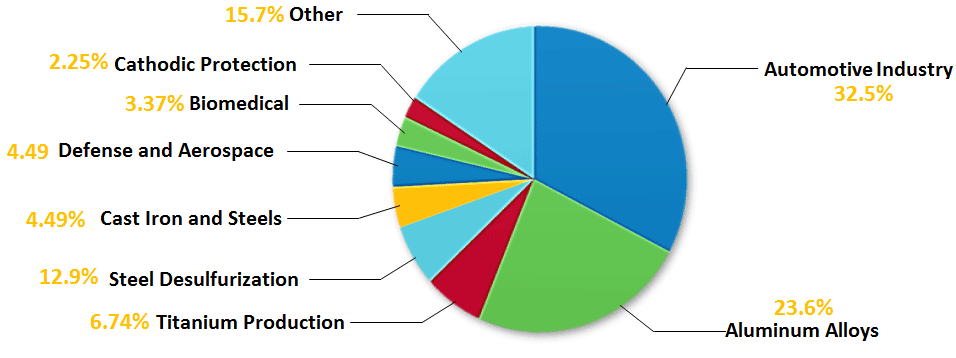

Magnesium main consumption is in die cast parts of automotives (32.5%) and aluminum alloy production (23.6%). Today, magnesium global production is 1 million tons per year and 85% of total magnesium production is in china and 15% is in other countries like: Ukraine, Malaysia, Russia, USA, Israel and etc. Magnesium production in china is mainly by silicothermic reduction (thermal reduction) and only USA and Israel produce magnesium by electrolysis route that uses mainly in military applications.

In the past years, magnesium alloys have poor mechanical properties but nowadays many research centers especially in Japan and European countries like Germany are studying and developing magnesium alloys with suitable mechanical and physical properties for applications like: automotive, military and aerospace industries.

European countries are the main consumers of magnesium alloys in automotive industry and annually need more than 200,000 tons magnesium and its alloys. International forecast institutes predict 2,000,000 tons magnesium demand in Europe till 2030. Persian Gulf Arabic countries due to the development of steel and aluminum industries are the other main consumers of magnesium in the world and need more than 30,000 tons magnesium annually.

Approximately 70 small magnesium production plants are closed in china due to international environmental pressures on the government therefore magnesium production as energy based industries move to countries with have rich natural gas energy resources.

Iran has rich dolomite mines as the main raw material for magnesium production and large natural gas resources. European and Arabic countries are the main target markets for magnesium and Iran is attractive magnesium supplier for these markets.

Construction 10 magnesium production plants (silicothermic reduction method) in Iran with the capacity of 12,000 tons per year results in 100,000 tons magnesium production in Iran and this country will be the second magnesium producer in the world. The main parameters that effect magnesium production are compared for Iran, Turkey and china in the table.

Expert design and R&D departments make us capable of executing various industrial projects from idea to implementation.

ARAMICO