Projects

We do MC, EMC, EPC and EPC-F for various projects in the field of metallurgy, mining & renewable energy

With the aim of constructing highly efficient, reliable and safe plants besides our longtime supporting services

Magnesium Plant

In recent years, due to the special properties of magnesium, the most important of which are low density, higher weight-to-strength ratio than aluminum, the ability to form intermetallic compounds, and high thermal activity, special attention has been paid to this valuable material. Magnesium is used as an alloying element for aluminum and steel, reducing or desulfurizing elements, etc. Magnesium is mostly produced by silicothermic reduction of dolomite ore.

Calcination Plants

The process of calcination (thermal decomposition) is generally referred to the reactions in which carbonate minerals such as dolomite, limestone, etc. are converted into oxide minerals at the right temperature and time in the furnace.

Mineral calcination processes are used in various industries such as lime and cement industries, gypsum production industries, glass industries, iron and steel industries, refractory industries, sugar and sugar industries, magnesium production industries, etc.

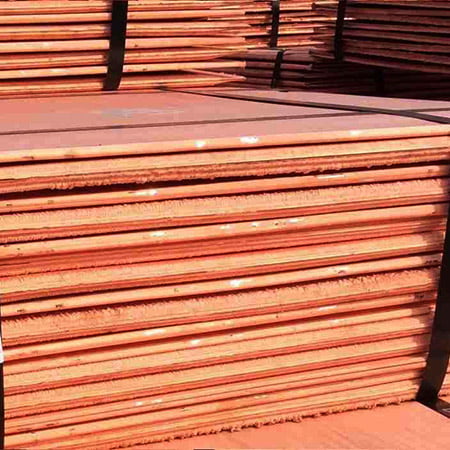

Copper Cathode Production Line

Copper is one of the main metals in the world and is one of the oldest metals discovered by mankind. Copper can be easily formed into different shapes. Due to the significant added value of copper metal production, its production is very profitable and many countries in the world are investing in copper cathode production plants.

Calcined Alumina (Alpha) Plant

Calcined alumina, aluminum oxide, is a widely used ceramic material and has mechanical properties such as good compressive strength and high hardness. It is also resistant to high temperatures, which makes it suitable as a refractory material. The high hardness of alumina makes it resistant to wear. Therefore, it is used in various cases, such as erosion-resistant coatings for pipes, ducts, pumps and valves, and sheaths for fibers, wires, etc. Alumina is used as a metal cutting tool tip due to its high hardness at high temperatures. Alumina is also the most widely used abrasive, which is generally used for ferrous alloys, high-tensile materials, and wood. Alumina is also used as a grinding material in a wide range of particle size reduction processes.

Electrofused Minerals Plant

Electrofused ceramic materials are produced using electric arc furnaces. Materials like alumina, silica, mullite and spinel can be produced with this method. Fused alumina has high density, low porosity, low permeability and high refractoriness. Because of these properties, this type of alumina is used in the production of abrasives and refractories. Young’s modulus of this type of alumina is higher than other abrasives and lower than SiC. The three main uses of fused alumina are abrasives, refractories, and sandblasting. Recently, this type of alumina is also used in the floor tile industry. Fused alumina can be produced as white fused or brown fused alumina.

Ammonium Sulfate Production Line

Ammonium sulfate is a solid crystalline form that is produced from the direct reaction between ammonia and sulfuric acid. Ammonium sulfate is mainly used as chemical fertilizer, which is valuable due to the simultaneous presence of sulfur and nitrogen. Ammonium sulfate is especially suitable for products such as rice, tea, citrus fruits and vine. A small percentage of ammonium sulfate is used in applications other than chemical fertilizers, which include the preparation of food supplements for cattle, medicinal use, insulating materials, tanning, fire extinguishing, food processes, fermentation, textile dyeing, and water purification.

Fluidized bed Mineral Roasting plants

Roasting is one of the metallurgical processes where ore is heated in the presence of excess air. The roasting process temperature is below the ore melting point. Generally, in this process, sulfide minerals are converted into oxide. A solid-gas thermal reaction happens during roasting. During this process lots of volatile gases is released for example in the roasting of sulfide ores SO2 is produced. The use of fluid bed reactors for roasting minerals is one of the modern methods that have high efficiency and lower energy consumption compared to conventional furnaces.

Briquetting Plants

The technology of briquetting is about 200 years old so various industries use it to improve the performance of their processes. The benefits of briquetting include the optimal use of by-products and low-efficiency materials in various industries. But in the last decade, new applications for briquetting have emerged, which has shown the importance of this industry more than ever. Briquetting is used in iron and steel, minerals (coal, salt, dolomite, manganese, ferroalloys, chemicals, agricultural chemical fertilizers and detergents, and sanitary materials.